The SEAL ROTATING Ring Stage 4 is a precision-engineered component designed for the CFM56-3 engine, exclusively powering the Boeing 737 Classic series, including the 737-300, 737-400, and 737-500 models. Manufactured with advanced heat-resistant alloys, this component ensures airtight sealing in the low-pressure turbine, optimizing engine efficiency, reducing fuel consumption, and extending the engine's operational life. Built to meet the stringent quality standards of CFM International, this part is trusted by airlines worldwide for its durability, performance, and safety.

The SEAL ROTATING Ring Stage 4 is a vital component of the CFM56-3 engine, a powerplant renowned for its reliability and efficiency. Designed specifically for the Boeing 737 Classic series, including the 737-300, 737-400, and 737-500 models, this precision-engineered part plays a crucial role in maintaining the engine's performance and ensuring safe, efficient operation.

In this article, we’ll explore the key features, functions, and benefits of the SEAL ROTATING Ring Stage 4 and why it is essential for modern aviation.

The SEAL ROTATING Ring Stage 4 is designed to withstand extreme operating conditions, ensuring the engine's smooth performance even under the most demanding circumstances. Here are its standout features:

Manufactured using advanced heat-resistant alloys that ensure durability and performance in high-temperature environments.

Corrosion-resistant properties extend the component's lifespan, reducing the need for frequent replacements.

Designed with exact tolerances to meet the stringent quality standards of CFM International.

Guarantees seamless integration with other engine parts, optimizing the engine's overall performance.

Provides an airtight seal for Stage 4 of the rotating turbine, preventing leaks and maintaining pressure within the engine.

Helps minimize energy losses, improving the engine's fuel efficiency.

The SEAL ROTATING Ring is built to endure prolonged use, reducing downtime and maintenance costs for airlines.

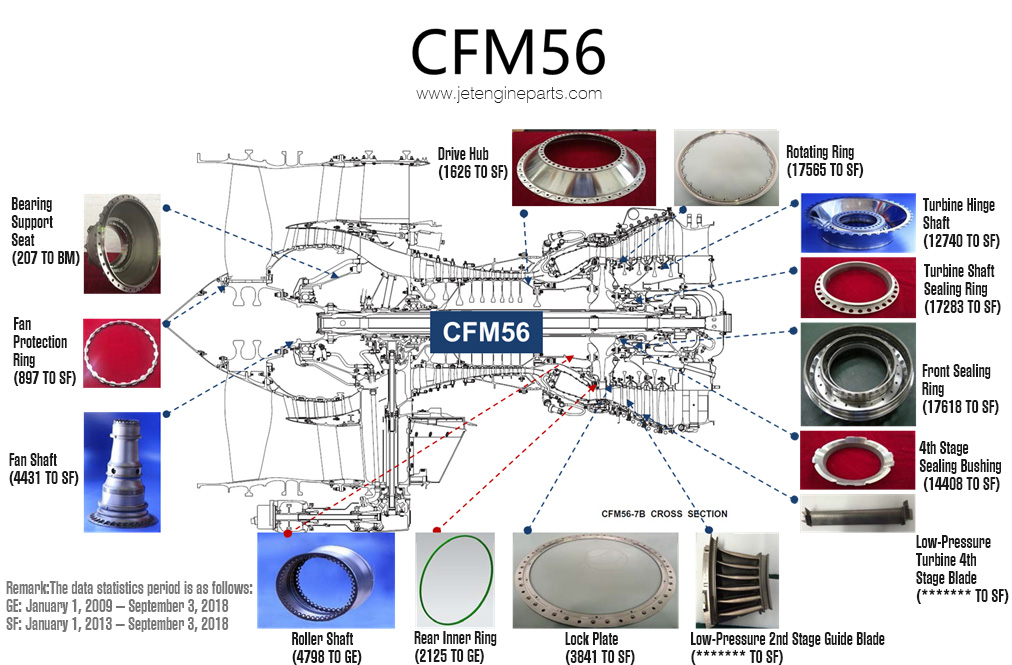

As an integral part of the low-pressure turbine (LPT) assembly, the SEAL ROTATING Ring Stage 4 contributes to the engine's efficiency and reliability. Its primary functions include:

The SEAL ROTATING Ring prevents air and gas leaks within the turbine, ensuring that the engine operates at peak efficiency. By maintaining pressure in the turbine, it allows the engine to generate the required thrust with minimal energy loss.

By optimizing the airflow and maintaining a consistent seal, the SEAL ROTATING Ring improves the turbine's overall efficiency. This translates to better fuel economy and lower emissions, aligning with modern aviation’s sustainability goals.

The component's robust design minimizes friction and vibration in the turbine assembly, reducing wear and tear on other engine parts. This prolongs the engine's operational life and lowers maintenance expenses.

Airlines and operators benefit significantly from the SEAL ROTATING Ring Stage 4. Some key advantages include:

Improved Fuel Efficiency: By maintaining optimal turbine performance, this component helps airlines reduce fuel consumption, leading to lower operating costs.

Enhanced Safety: High-quality materials and precision manufacturing reduce the risk of in-flight mechanical failures.

Extended Engine Life: Durable construction ensures longer intervals between replacements, minimizing downtime and maintenance costs.

Compatibility Across Models: Specifically designed for the CFM56-3 engine, the SEAL ROTATING Ring supports the Boeing 737 Classic series, which continues to be a workhorse for airlines worldwide.

The aviation industry demands the highest standards of safety and reliability. Using high-quality components, such as the SEAL ROTATING Ring Stage 4, is critical to maintaining fleet performance and safety. Here’s why:

Safety Assurance: Reliable components minimize the risk of mechanical failures during operation.

Operational Efficiency: High-precision parts ensure that engines operate smoothly and efficiently.

Cost Savings: Durable materials reduce the frequency of replacements, lowering long-term maintenance costs.

Regular maintenance of the CFM56-3 engine is vital to ensure safety and performance. Replacing worn-out components like the SEAL ROTATING Ring Stage 4 prevents potential issues and extends the engine’s operational life.

Ease of Replacement: Designed for quick and seamless integration with existing systems.

Readily Available Parts: High-quality spares are available from trusted suppliers like Liyan International.

Reduced Lifecycle Costs: Regular maintenance lowers overall expenses for operators.

When sourcing components for the CFM56-3 engine, reliability and quality are paramount. Liyan International Manufacturing Co., Ltd. specializes in producing precision-engineered parts, including the SEAL ROTATING Ring Stage 4.

Advanced Manufacturing: State-of-the-art equipment ensures consistent quality and precision.

Strict Quality Standards: All parts meet international aviation certifications, including AS9100D and NADCAP.

Global Reputation: Trusted by leading airlines and operators worldwide.

Comprehensive Customer Support: Dedicated support to help clients find the right solutions for their fleets.

The SEAL ROTATING Ring Stage 4 is more than just a component; it is a critical element in ensuring the safety, efficiency, and reliability of the CFM56-3 engine. Its robust design and advanced engineering make it indispensable for the Boeing 737 Classic series, a cornerstone of modern aviation.

By investing in high-quality components like this, airlines can maximize uptime, enhance fuel efficiency, and ensure safe operations for passengers and crew.

The SEAL ROTATING Ring Stage 4 for the CFM56-3 engine represents the pinnacle of precision engineering. Its role in maintaining turbine efficiency, reducing wear, and ensuring reliable engine operation underscores its importance in the aviation industry.

For airlines and operators seeking durable, high-quality components, Liyan International offers trusted solutions to support fleet performance and safety. Contact us today to learn more about our range of products and how we can meet your aviation needs.

Contact: Mr. Chris Zhang

Phone: 86-18068808880

Tel: 86-13905198660

Email: jetengineparts@aliyun.com

Add: jetengineparts@aliyun.com

We chat