Liyan International specializes in manufacturing high-precision components for the CFM56 engine, a globally recognized leader in aviation technology. Our products include fan shafts, sealing rings, engine casings, guide vanes, and bearing supports, all engineered to enhance the performance, reliability, and efficiency of the CFM56 engine. Certified to international standards such as AS9100D and NADCAP, we are a trusted supplier to leading aerospace companies, ensuring world-class quality and innovation.

The CFM56 engine is manufactured by CFM International, a 50/50 joint venture between two major aerospace companies:

GE Aviation (General Electric) - Based in the United States. GE Aviation is responsible for the design and production of the engine’s core, which includes the high-pressure compressor, high-pressure turbine, and combustor.

Safran Aircraft Engines - Based in France. Safran is responsible for the fan, low-pressure turbine, and the external casing of the engine.

CFM International was established in 1974 specifically to develop and produce the CFM56 series of engines. The name "CFM56" is derived from the CF6 engine (a GE product) and the M56 military engine program (a Safran product), combining their expertise into one product line.

Since its introduction, the CFM56 engine has become one of the most successful and widely used jet engines in aviation, powering commercial and military aircraft globally.

The CFM56 engine is one of the most iconic and widely used aircraft engines in aviation history. This engine has become the backbone of commercial aviation, powering thousands of aircraft globally. Its remarkable reliability, efficiency, and adaptability have solidified its place as a leading choice for both narrow-body and military aircraft.

The name CFM56 originates from the combination of engine designations from GE Aviation and Safran, which together form the joint venture CFM International.

CFM:

CF: Represents GE's CF6 engine series, a successful line of high-bypass turbofan engines.

M: Comes from Snecma's (now Safran) original M56 engine project.

56:

The number 56 is derived directly from Snecma's M56 project designation.

Therefore, CFM56 signifies the collaboration between GE and Snecma:

CF (from GE's CF6 engine series) + M56 (Snecma's project) = CFM56

This naming reflects the joint effort in developing the engine, combining GE's and Snecma's expertise. The CFM56 engine series has since become one of the most successful and widely used jet engines in aviation history, powering a variety of commercial and military aircraft worldwide.

The CFM56 engine is one of the most widely used and successful jet engines in the aviation industry. It powers a variety of commercial and military aircraft. Here's a detailed breakdown:

A318 (CFM56-5B)

A319 (CFM56-5A/5B)

A320 (CFM56-5A/5B)

A321 (CFM56-5B)

The CFM56 is one of the two engine options for the Airbus A320 family, alongside the IAE V2500.

737-300/400/500 (Classic) (CFM56-3)

737-600/700/800/900 (Next Generation) (CFM56-7B)

The CFM56 is the exclusive engine for the 737 Classic and Next Generation (NG) series.

DC-8-70 Series (CFM56-2)

Older DC-8 aircraft were retrofitted with CFM56 engines, replacing the original JT3C turbojets to improve performance and fuel efficiency.

Retrofitted versions of the MD-80 (some models) can use the CFM56-2 engine.

KC-135R/T models use the CFM56-2, replacing the original Pratt & Whitney J57 engines to improve fuel efficiency and reliability.

This airborne warning and control aircraft uses the CFM56-2.

Utilizes the CFM56-2 for its command and control missions.

A military variant of the Boeing 737 NG, the P-8 is powered by the CFM56-7B.

Another military adaptation of the Boeing 737 NG, also powered by the CFM56-7B.

Retrofitted 707s use the CFM56-2, primarily for cargo operations.

Modernized DC-8 freighters employ the CFM56-2 for increased efficiency.

The CFM56 has been retrofitted onto older aircraft (e.g., the Douglas DC-8 and KC-135) to extend their operational life, reduce fuel consumption, and meet modern noise and emission standards.

The CFM56 has been a versatile and widely used engine due to its adaptability, fuel efficiency, and reliability. With over 33,000 engines produced, it powers both narrow-body commercial aircraft and specialized military platforms, cementing its place as one of the most successful jet engines in aviation history.

The cost of a CFM56 engine varies depending on the specific model, configuration, and the commercial terms of the purchase. Here’s a general range based on the most common variants:

CFM56-5A/5B/7B (Commercial Use):

The price for new engines typically ranges between $10 million and $15 million USD per engine, depending on specifications, thrust requirements, and airline-negotiated discounts.

Overhauled/Used Engines:

Used or overhauled CFM56 engines cost significantly less, typically ranging between $3 million and $7 million USD, depending on the number of flight cycles completed, remaining service life, and maintenance history.

Military Applications (CFM56-2):

Military variants, such as those used on the KC-135 or Boeing E-3 Sentry, might have costs adjusted for specific mission requirements, typically in the same range as commercial models.

Engine Model: Variants like the CFM56-5B (used on Airbus A320 family) and CFM56-7B (exclusive to Boeing 737 NG) may have different prices based on thrust rating and application.

Thrust Rating: Engines with higher thrust capabilities cost more due to added engineering and materials.

Custom Features: Optional modifications for fuel efficiency, noise reduction, or compatibility with specific aircraft models can increase costs.

Maintenance Agreements: Airlines often negotiate long-term service and maintenance packages, which may affect the upfront cost.

Market Dynamics: Availability, production demand, and airline fleet expansions influence the pricing.

In addition to the upfront purchase price, airlines must consider operating costs:

Maintenance Costs: Estimated at $1 million to $2 million per year per engine for airlines, depending on utilization.

Fuel Efficiency: Fuel consumption is a critical factor, and the CFM56 series is known for its efficiency compared to older models.

The CFM56 remains a highly sought-after engine for its reliability, availability of spare parts, and cost-effective operation, making it one of the most popular engines in aviation history.

The CFM56 engine is a high-bypass turbofan engine that combines cutting-edge technology with robust engineering. Below are its defining features:

High Efficiency

The CFM56 achieves exceptional fuel efficiency due to its advanced aerodynamic design and high bypass ratio. This not only reduces operating costs for airlines but also minimizes environmental impact.

Modular Design

The engine's modular construction simplifies maintenance, reducing downtime and repair costs. This feature ensures higher operational availability, which is critical for airlines.

Durability and Reliability

With a Mean Time Between Overhaul (MTBO) of over 30,000 flight hours, the CFM56 has set industry standards for reliability.

Versatility

The CFM56 powers multiple aircraft models, including the Airbus A320 family, Boeing 737 series, and various military aircraft. Its adaptability to different platforms has made it a versatile solution for diverse aviation needs.

Environmental Impact

The engine is designed to meet stringent noise and emission standards, making it a sustainable option for modern aviation.

The CFM56 engine is renowned for its widespread application across both commercial and military sectors:

Commercial Aviation:

The engine powers popular aircraft like the Airbus A320 and Boeing 737, which form the backbone of short- and medium-haul flights worldwide.

Military Aviation:

Several military platforms, including the Boeing E-3 Sentry (AWACS) and KC-135 Stratotanker, utilize the CFM56 for its reliability and performance.

Freighter Aircraft:

Its robust performance makes it suitable for cargo aircraft, enabling efficient transportation of goods.

As a globally recognized leader in aerospace component manufacturing, Liyan International Manufacturing Co., Ltd. has established itself as a key supplier for the iconic CFM56 engine. This high-performance turbofan engine, developed by CFM International, powers numerous commercial and military aircraft worldwide. Liyan International’s contribution to the CFM56 engine program reflects its commitment to precision, innovation, and quality in the aviation sector.

Liyan International plays a crucial role in supporting the operation and longevity of the CFM56 through the production of essential components.

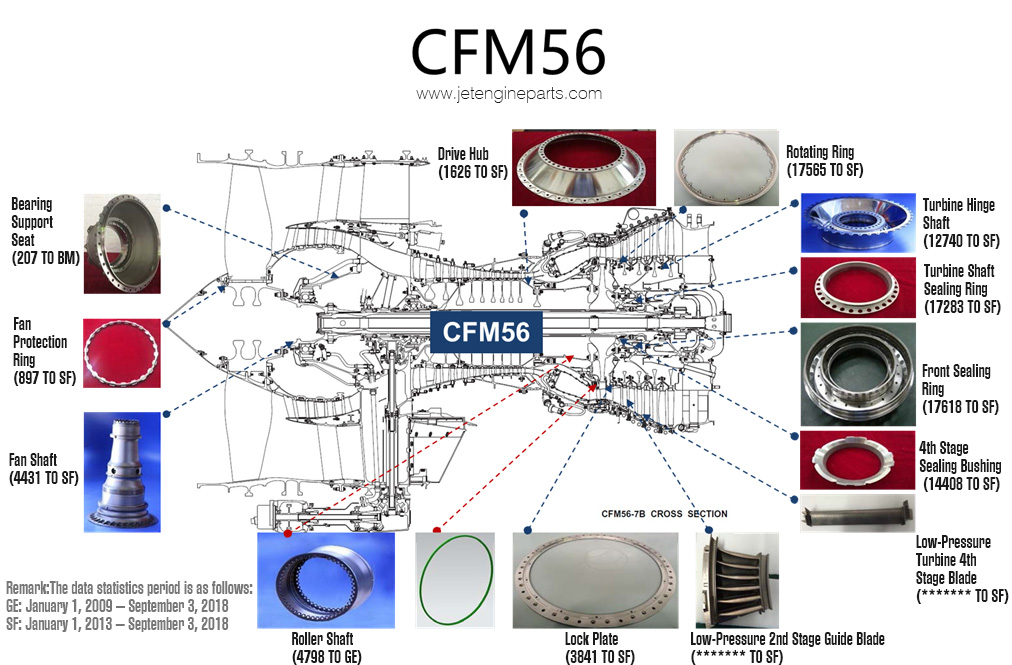

Liyan International Manufacturing Co., Ltd. plays a crucial role in the success of the CFM56 engine by supplying key components. The company specializes in manufacturing parts such as:

Fan Shafts and Rings

Essential for maintaining the engine's balance and performance.

Turbine Sealing Rings

Ensure optimal airflow and prevent leakage in the turbine section.

Engine Casings

Provide structural support and house the core components of the engine.

Bearing Supports

Critical for reducing friction and enhancing the engine's operational longevity.

Guide Vanes

Contribute to the efficient direction of airflow, improving overall engine efficiency.

Liyan International’s high-precision manufacturing processes and adherence to global quality standards, such as AS9100D and NADCAP certifications, make it a trusted supplier for the CFM56 engine program.

Since its introduction in the 1970s, the CFM56 engine has revolutionized the aviation industry. Key milestones include:

Reliability Record:

Over 1 billion flight hours accumulated globally, showcasing its unmatched reliability.

Fleet Size:

More than 33,000 engines delivered, powering over 10,000 aircraft worldwide.

Fuel Efficiency:

Continuous improvements in engine technology have enabled airlines to reduce fuel consumption by up to 15%, translating into billions of dollars in savings.

Although the CFM56 program has transitioned to newer-generation engines like the LEAP series, its legacy continues to shape modern aviation. Airlines still rely on its performance for existing fleets, and its parts remain in high demand for maintenance and overhaul.

Liyan International is committed to supporting the global aviation industry by supplying precision-engineered components for the CFM56 and other advanced engines. Through innovation and quality, the company aims to contribute to the future of sustainable and efficient air travel.

The CFM56 engine exemplifies the pinnacle of aviation engineering, with its unmatched reliability, efficiency, and versatility. Its widespread adoption across commercial and military platforms has cemented its status as one of the most successful aircraft engines in history. With industry leaders like Liyan International providing essential components, the CFM56 continues to set benchmarks in aerospace innovation and operational excellence.

With over two decades of experience, Liyan International specializes in designing and manufacturing high-precision components that are integral to the performance of the CFM56 engine. The company adheres to strict quality standards, including AS9100D and NADCAP certifications, ensuring excellence in every product.

Fan Shafts and Protection Rings

Liyan manufactures durable and precision-engineered fan shafts and protection rings, which are essential for ensuring the fan's stability and reducing wear during operation.

Turbine Sealing Rings

High-quality sealing rings that improve the efficiency of the turbine by minimizing airflow leakage, enhancing overall engine performance.

Bearing Supports

Critical components that ensure smooth operation by reducing friction in high-speed rotations.

Engine Casings

Robust and precisely machined engine casings that house core engine components, providing structural integrity and thermal protection.

Guide Vanes and Stages

Guide vanes for directing airflow efficiently through the engine, ensuring optimized performance and reduced fuel consumption.

Liyan International is trusted by some of the biggest names in the aerospace industry, including GE Aviation, Safran, and Collins Aerospace. Here’s what sets Liyan apart:

Precision Engineering

With advanced production facilities and over 150 state-of-the-art machines, including 5-axis lathes, Liyan delivers components that meet the strictest tolerances.

Global Standards Compliance

Certifications like AS9100D and NADCAP showcase Liyan’s commitment to quality, safety, and reliability in aerospace manufacturing.

Expertise and Experience

With over 20 years of experience and a skilled team of 383 employees, Liyan combines innovation with expertise to deliver world-class products.

Global Recognition

Liyan is a key supplier for the CFM56 engine, which powers over 10,000 aircraft worldwide. Its products ensure reliability, safety, and efficiency for airlines and military operators.

The components manufactured by Liyan International play a pivotal role in the success of the CFM56 engine. Airlines and operators worldwide rely on Liyan's parts for their durability, precision, and cost-effectiveness. Key benefits include:

Reduced Downtime: High-quality parts minimize the need for frequent maintenance, ensuring smooth operation.

Extended Engine Life: Liyan’s components help maintain the engine’s performance over its lifecycle, reducing long-term costs.

Environmental Compliance: The precision of Liyan’s parts contributes to the engine’s ability to meet stringent noise and emission standards.

Liyan International is not just a supplier; it is a partner in innovation and sustainability. The company is expanding its production capacity with new investments, including a state-of-the-art facility in Sha Wen, scheduled to open in 2025. This expansion will enable Liyan to support next-generation engines while continuing its legacy with the CFM56.

By leveraging its technological expertise and commitment to excellence, Liyan aims to remain a cornerstone in the global aerospace supply chain, driving innovation and efficiency in the aviation industry.

The CFM56 engine is a symbol of reliability and innovation in the aviation world, and Liyan International is proud to be a key contributor to its success. Through precision-engineered components, stringent quality standards, and a dedication to meeting customer needs, Liyan International ensures that the CFM56 continues to power the skies with unmatched efficiency and dependability.

If you’re looking for a trusted partner in aerospace component manufacturing, Liyan International is your go-to source for excellence and innovation. Contact us today to learn more about how our components can support your aviation needs.

Contact: Mr. Chris Zhang

Phone: 86-18068808880

Tel: 86-13905198660

Email: jetengineparts@aliyun.com

Add: jetengineparts@aliyun.com

We chat