The Stage 4 Sealing Bushing is a precision-engineered component essential for the CFM56 engine, powering aircraft such as the Boeing 737 series and Airbus A320 family. This component ensures optimal sealing within the low-pressure turbine system, reducing airflow leaks, maintaining engine pressure, and enhancing overall efficiency. Manufactured using advanced heat-resistant alloys, it withstands extreme temperatures and corrosion, ensuring long-term durability and reliability. Designed to meet CFM International's exacting standards, the Stage 4 Sealing Bushing plays a vital role in improving fuel efficiency, reducing maintenance costs, and extending engine lifespan.

The Stage 4 Sealing Bushing, also known as the Stage 4 Seal Sleeve, is a critical component in the CFM56 engine. It plays an essential role in maintaining efficiency and reliability by providing effective sealing in the low-pressure turbine system. Designed to prevent airflow leaks, this component ensures optimal engine performance and durability, especially in demanding aviation conditions.

Let’s explore the features, functions, and benefits of this precision-engineered part and its contribution to modern aviation.

The Stage 4 Sealing Bushing is designed to meet the rigorous demands of the CFM56 engine, ensuring long-term reliability and efficiency.

Heat Resistance: Manufactured from high-performance, heat-resistant alloys, it can withstand extreme temperatures generated in the low-pressure turbine system.

Corrosion Resistance: The bushing is engineered to resist wear and corrosion caused by constant exposure to airflow and contaminants.

Exact Tolerances: The sealing bushing is crafted to meet the stringent standards of CFM International, ensuring a perfect fit and compatibility with the CFM56 engine.

Aerodynamic Optimization: Its design minimizes energy losses by maintaining a consistent seal and improving airflow.

Leak Prevention: Effectively prevents air leaks within the turbine system, maintaining the pressure required for efficient operation.

Enhanced Efficiency: By reducing energy losses, it contributes to better fuel efficiency and engine performance.

As an integral part of the CFM56 engine's low-pressure turbine system, the Stage 4 Sealing Bushing serves several critical functions:

The bushing ensures that pressurized air remains within the designated turbine system, preventing energy loss and maintaining consistent thrust levels.

By optimizing the airflow, the sealing bushing helps the engine achieve better fuel efficiency and reduced emissions, aligning with modern aviation's sustainability goals.

The bushing prevents debris and contaminants from entering the turbine system, safeguarding delicate components like rotors and blades.

By minimizing wear and tear on other engine parts, the sealing bushing extends the overall lifespan of the engine, reducing maintenance costs for airlines.

The Stage 4 Sealing Bushing is more than just a part of the turbine system. Its impact on engine performance, safety, and reliability is significant.

Effective sealing reduces energy losses, improving combustion efficiency and lowering fuel consumption.

By maintaining proper sealing and airflow, the bushing reduces the risk of mechanical failures, ensuring safer flight operations.

Its durable construction minimizes the need for frequent replacements, helping airlines reduce long-term maintenance expenses.

Airlines using aircraft equipped with CFM56 engines benefit significantly from high-quality components like the Stage 4 Sealing Bushing. Here’s how:

The durable design and resistance to wear lower the frequency of repairs and replacements.

The bushing’s superior sealing capabilities enhance fuel economy, reducing operational costs for airlines.

Precision-engineered components ensure consistent performance, minimizing downtime and delays.

The Stage 4 Sealing Bushing is designed for use in CFM56 engines, making it suitable for a range of aircraft, including the Boeing 737 series and Airbus A320 family.

When sourcing critical aviation components like the Stage 4 Sealing Bushing, quality and reliability are paramount. Liyan International Manufacturing Co., Ltd. specializes in precision-engineered parts that meet the highest standards in the aviation industry.

Liyan International uses state-of-the-art equipment to craft components that meet certifications such as AS9100D and NADCAP.

With a global reputation for delivering quality, Liyan International supplies parts to leading airlines and aircraft operators.

Dedicated support ensures that clients receive the right components for their specific needs, enhancing fleet reliability and performance.

Regular maintenance is essential for ensuring the safety and performance of the CFM56 engine. Replacing worn-out components, such as the Stage 4 Sealing Bushing, prevents potential issues and extends the engine’s operational life.

Ease of Replacement: Designed for seamless integration, the sealing bushing minimizes downtime during maintenance.

Readily Available Parts: High-quality spares are available from trusted suppliers like Liyan International.

Cost Savings: Regular maintenance reduces long-term operational costs by ensuring optimal engine performance.

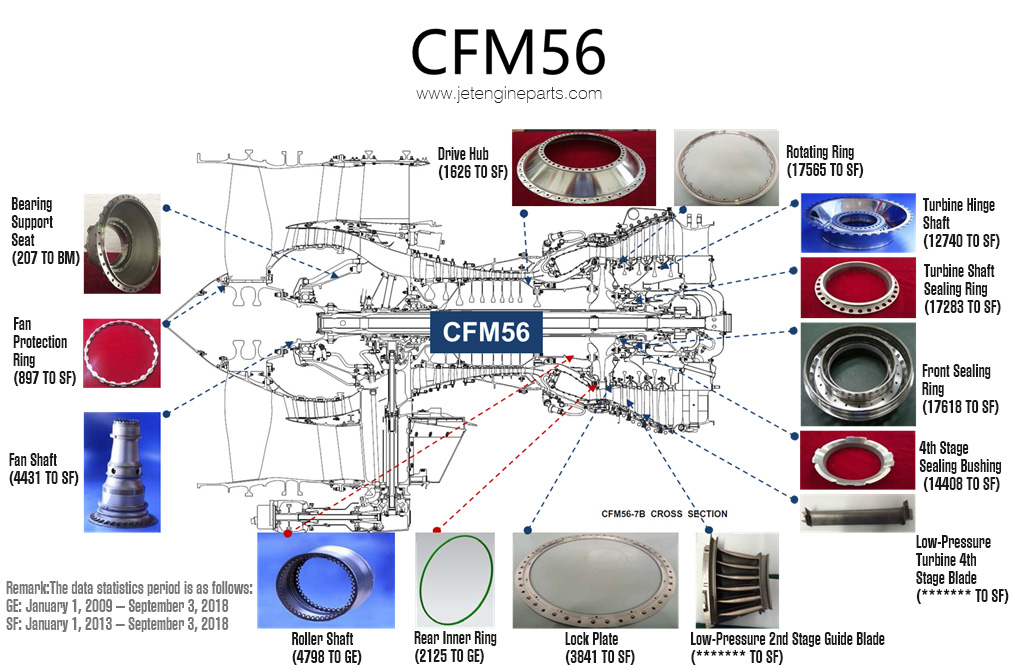

The CFM56 engine, developed by CFM International—a joint venture between GE Aviation and Safran Aircraft Engines—has set the benchmark for reliability and efficiency in modern aviation. Components like the Stage 4 Sealing Bushing contribute to its reputation as one of the most trusted powerplants for commercial aircraft.

Proven Reliability: Millions of flight hours logged globally.

Fuel Efficiency: Optimized for short- to medium-haul flights, reducing costs for operators.

Durability: Advanced materials and precision engineering ensure long-lasting performance.

The Stage 4 Sealing Bushing is a small yet critical component that ensures the efficiency, safety, and reliability of the CFM56 engine. Its advanced design and robust materials make it indispensable for airlines looking to optimize performance and reduce operational costs.

For durable, high-performance engine components, Liyan International offers trusted solutions. Contact us today to learn more about our products and how we can support your aviation needs.

Contact: Mr. Chris Zhang

Phone: 86-18068808880

Tel: 86-13905198660

Email: jetengineparts@aliyun.com

Add: jetengineparts@aliyun.com

We chat