Manufacturer of turned components for the aerospace industry: Rotating Rings (Stages 2/3/4/5) are precision-engineered components essential for maintaining turbine stability in LEAP-1B engines. Crafted with advanced materials, these rings ensure smooth energy transfer, reduce wear, and enhance overall engine performance under extreme pressure and temperature conditions.

Modern aircraft engines rely on precision engineering to deliver efficiency, reliability, and performance.

Our machining capabilities allow us to deliver high-quality components with unmatched precision. We use advanced CNC machining and CNC turning to create parts that meet the strict standards of aerospace applications. These processes ensure tight tolerances and reliable performance for critical aircraft engine components.

Among the critical components in the LEAP-1B engine are the Rotating Rings for Stages 2, 3, 4, and 5. These rings are essential for maintaining turbine stability and enabling seamless energy transfer during engine operation.

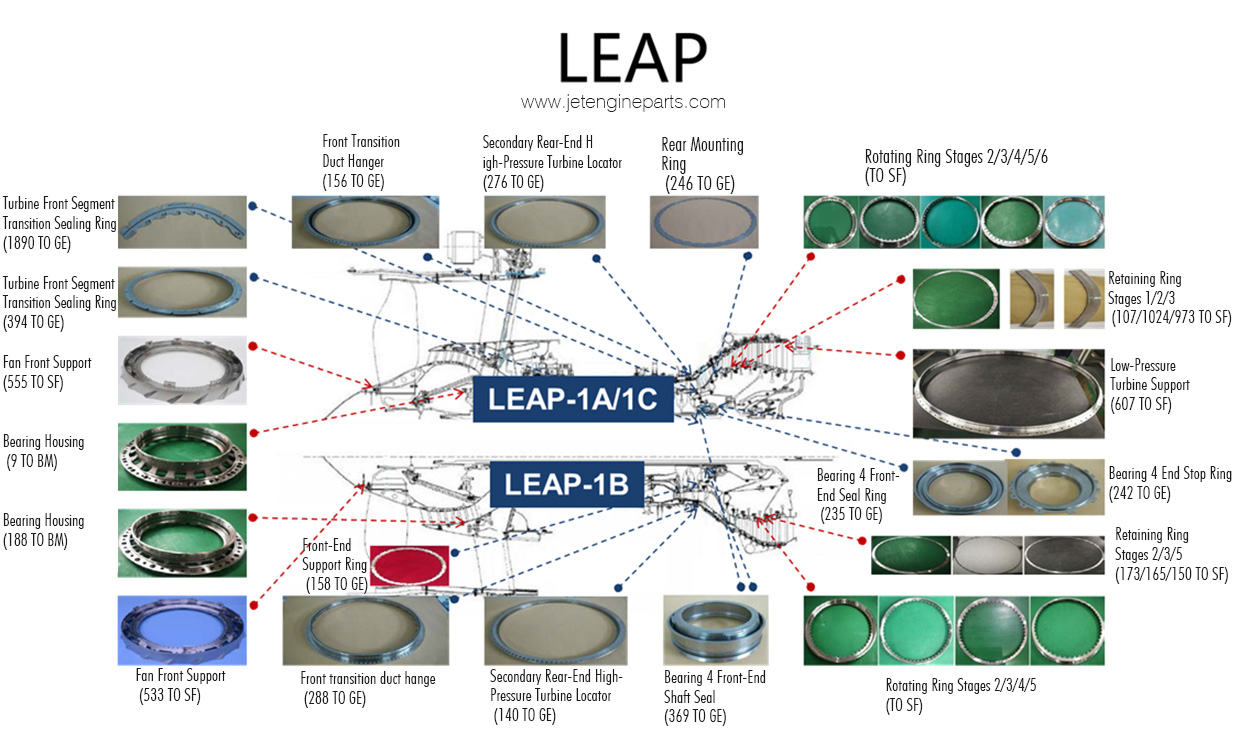

As a manufacturer of Aircraft Engine, Liyan International specializes in high-quality parts for both LEAP-1A/1C and LEAP-1B engines. Our components ensure optimal performance and precision across a wide range of aerospace applications.

Rotating rings are integral parts of the high-pressure turbine section in turbofan engines like the LEAP-1B. These precision aerospace components are designed to stabilize turbine rotation and facilitate energy transfer across multiple stages. These rings keep turbine blades aligned and reduce vibrations. So that they work efficiently under high pressure and extreme heat.

Crafted using cutting-edge aerospace machining services, these rings meet the tight tolerances required for high-performance engines. Titanium alloys and ceramic composites strengthen the engine's components. These materials enhance durability and resist wear in the engine's hot section.

Enhanced Stability: The rings ensure consistent alignment and smooth rotation of the turbine blades, even during high-speed operations.

Durability in Harsh Conditions: Designed for extreme environments, they withstand high temperatures and pressures without deformation.

Optimized Energy Transfer: The rings facilitate efficient transfer of rotational energy across turbine stages, enhancing engine thrust.

Precision CNC Machining: Manufactured with advanced CNC machining aerospace techniques, these rings meet the highest quality standards.

During engine operation, air flows into the combustion chamber through an advanced air intake system. The combustion process generates energy, driving the turbine blades. The Rotating Rings (Stages 2/3/4/5) stabilize this rotation, ensuring seamless energy transfer between stages.

Here’s how each stage contributes:

Stage 2: Begins the energy transfer process by stabilizing initial rotation.

Stage 3: Maintains turbine alignment as gases expand further.

Stages 4 and 5: Ensure smooth energy transfer to subsequent turbine components, maximizing thrust efficiency.

Improved Engine Performance: Stable turbine rotation improves fuel use and boosts thrust.

Reduced Maintenance Costs: Precise alignment lowers wear on turbine blades and reduces repair needs.

Increased Safety: Proper alignment prevents mechanical failures, ensuring safer flights.

Extended Lifespan: Strong materials and accurate machining make engine parts last longer.

The Rotating Rings (Stages 2/3/4/5) are integral to the LEAP-1B engines, which power advanced aircraft such as the Boeing 737 MAX. These precision machined aerospace parts ensure that the engines meet the stringent demands of the aerospace industry. Their role in optimizing performance and fuel efficiency makes them essential in both commercial and military aircraft applications.

At Liyan International, we provide a comprehensive range of precision machined components for the aerospace sector. Our expertise in CNC machining services allows us to deliver high-quality aircraft components with tight tolerances and exceptional durability.

Front Transition Duct Hanger (156 TO GE)

Turbine Front Segment Transition Sealing Ring (1890 TO GE / 394 TO GE)

Fan Front Support (555 TO SF)

Bearing Housing (9 TO BM / 188 TO BM)

Secondary Rear-End High-Pressure Turbine Locator (276 TO GE)

Rear Mounting Ring (246 TO GE)

Rotating Rings (Stages 2/3/4/5/6)

Retaining Rings (Stages 1/2/3)

Low-Pressure Turbine Support (607 TO SF)

Front Transition Duct Hanger (288 TO GE)

Front-End Support Ring (158 TO GE)

Fan Front Support (533 TO SF)

Secondary Rear-End High-Pressure Turbine Locator (140 TO GE)

Rotating Rings (Stages 2/3/4/5)

Bearing 4 Front-End Seal Ring (235 TO GE)

Bearing 4 End Stop Ring (242 TO GE)

Retaining Rings (Stages 2/3/5)

As a trusted manufacturer, we provide high-quality parts that meet the demanding requirements of aerospace machining services.

Precision Manufacturing: Tight tolerances and exceptional accuracy.

Advanced Capabilities: Expertise in CNC milling and turning.

Durable Solutions: Parts designed for longevity in extreme conditions.

Cost Efficiency: Reduce functional costs with reliable components.

Expertise in Aerospace Applications: Decades of experience in aerospace manufacturing and supply chain solutions.

The Rotating Rings (Stages 2/3/4/5) are critical to the performance and reliability of LEAP-1B engines. They ensure turbine stability, enhance energy transfer, and contribute to overall fuel efficiency. At Liyan International, we deliver high-quality precision aerospace components that elevate engine performance while reducing maintenance costs.

For precision machined aerospace parts, trust Liyan International. Contact us today to learn more about our aerospace machining services and innovative solutions.

Contact: Sales Dept.

Phone: 86-18068808880

Tel: 86-13905198660

Email: jetengineparts@aliyun.com

Add: No. 555, Yangzijiang Road, New District, Zhenjiang City, Jiangsu Province, China

We chat