The Rear Stator Seal for Bearing 4 is a critical component of the LEAP-1B aircraft engine, designed to provide efficient sealing and ensure optimal lubrication in high-performance turbofan engines. It prevents oil leakage, blocks contaminants, and enhances the durability of sensitive engine parts. Crafted with advanced materials, it withstands extreme temperatures and pressures, ensuring reliable operation and reduced maintenance costs.

Modern aircraft rely on advanced jet engine components to deliver exceptional performance and fuel efficiency. In a gas turbine, every component plays a vital role in ensuring reliability.

Military aircraft rely on precise turbine blades to ensure efficient energy transfer as air passes through the engine's high-performance systems.

Among these, the Rear Stator Seal for Bearing 4 stands out as a critical component of the LEAP-1B engine, safeguarding both performance and durability.

Renowned manufacturers like Rolls Royce and CFM International lead the industry in developing high-bypass turbofan engines. These engines propel the aircraft efficiently while reducing environmental impact.

The Rear Stator Seal for Bearing 4 is an advanced sealing component located at the rear of the bearing system in LEAP-1B engines. Its primary function is to provide an airtight seal, preventing the leakage of lubricating oil and blocking contaminants from entering the bearing chamber.

This aircraft engine component is designed for extreme conditions, ensuring the engine operates seamlessly under high temperature and high pressure. The seal enhances engine reliability and extends its working life.

Efficient Sealing

The seal effectively prevents oil leakage and keeps contaminants out. This protects sensitive engine parts and ensures smooth operations.

Built to Withstand Harsh Conditions

Made from high-performance materials such as titanium alloys and ceramic composites, the seal can endure the high-temperature environment of the hot section.

Enhanced Durability

Its robust construction minimizes wear, reducing maintenance requirements and prolonging the lifespan of the bearing system.

Improved Engine Efficiency

By maintaining proper lubrication and reducing energy losses, the Rear Stator Seal enhances the overall fuel efficiency of the engine.

The seal forms a tight barrier around the bearing assembly. This prevents lubricating oil from escaping and stops contaminants from entering the engine's core. During operation, the air intake system channels air into the combustion chamber. This helps turbines, which drive the aircraft, perform at peak efficiency.

The Rear Stator Seal stabilizes the engine, ensuring consistent performance. By reducing friction and protecting bearings from debris, it plays a critical role in the engine's durability and efficiency.

Reliable Performance

The seal ensures optimal lubrication, reducing the risk of mechanical failures.

Lower Maintenance Costs

By preventing wear and contamination, it minimizes the frequency of repairs and replacements.

Improved Safety

A secure sealing system enhances the safety and reliability of the engine during high-speed operations.

Eco-Friendly Operation

Efficient sealing reduces fuel consumption and emissions, supporting sustainable aviation goals.

The Rear Stator Seal for Bearing 4 is an integral part of LEAP-1B engines, powering aircraft such as the Boeing 737 MAX. These turbofan engines are known for their fuel efficiency and advanced engineering. By ensuring precise sealing and reliable lubrication, the Rear Stator Seal contributes to the engine's outstanding performance.

At Liyan International, we specialize in high-quality aircraft jet engine components. Our parts meet the strictest industry standards, ensuring exceptional performance and durability.

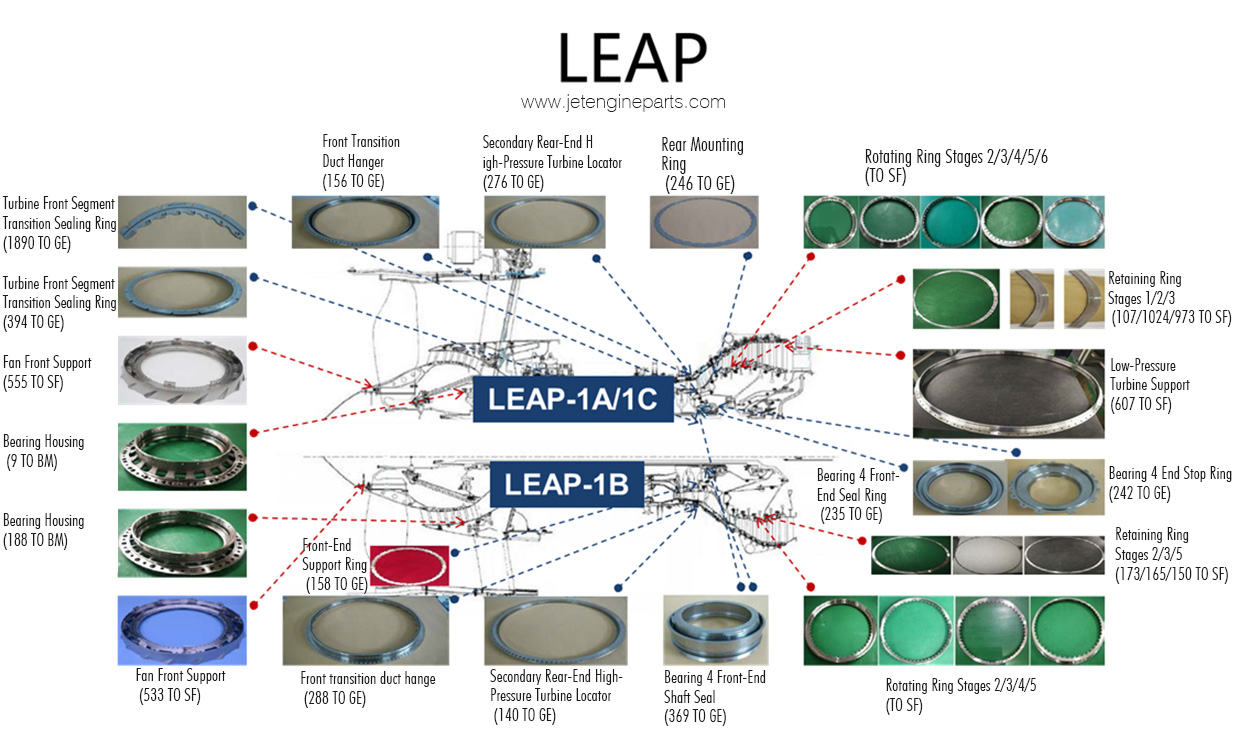

Front Transition Duct Hanger (156 TO GE): Ensures smooth airflow transition.

Turbine Front Segment Transition Sealing Ring (1890 TO GE / 394 TO GE): Protects the turbine's front segment.

Fan Front Support (555 TO SF): Stabilizes the fan blade assembly.

Bearing Housing (9 TO BM / 188 TO BM): Supports and aligns engine bearings.

Secondary Rear-End High-Pressure Turbine Locator (276 TO GE): Precisely positions the turbine.

Rear Mounting Ring (246 TO GE): Provides rear-end assembly support.

Rotating Rings (Stages 2/3/4/5/6): Enhances turbine rotation.

Retaining Rings (Stages 1/2/3): Secures critical components.

Low-Pressure Turbine Support (607 TO SF): Stabilizes the low-pressure turbine assembly.

Front Transition Duct Hanger (288 TO GE): Supports airflow in the front section.

Front-End Support Ring (158 TO GE): Provides front section stability.

Fan Front Support (533 TO SF): Maintains fan blade balance.

Secondary Rear-End High-Pressure Turbine Locator (140 TO GE): Ensures precise turbine positioning.

Rotating Rings (Stages 2/3/4/5): Improves turbine performance.

Bearing 4 Front-End Seal Ring (235 TO GE): Protects front-end bearings.

Bearing 4 End Stop Ring (242 TO GE): Secures the bearing assembly.

Retaining Rings (Stages 2/3/5): Holds turbine components securely.

We are committed to providing innovative solutions for modern aviation. With years of experience and a focus on quality, our components enhance the performance, efficiency, and longevity of jet engines.

Precision Manufacturing: Every part is crafted to exact specifications.

Durability: Designed to withstand extreme conditions.

Cost-Effective Solutions: Reduce maintenance costs and improve engine performance.

Expertise: Proven experience in supplying critical aircraft engine components.

The Rear Stator Seal for Bearing 4 is more than just a component. It’s a cornerstone of modern turbofan engine technology. By ensuring proper sealing, it enhances engine efficiency, reduces maintenance costs, and supports sustainable aviation.

For high-quality aircraft jet engine components, trust Liyan International. Contact us today to learn more about how our innovative solutions can elevate your engines' performance.

Contact: Sales Dept.

Phone: 86-18068808880

Tel: 86-13905198660

Email: jetengineparts@aliyun.com

Add: No. 555, Yangzijiang Road, New District, Zhenjiang City, Jiangsu Province, China

We chat