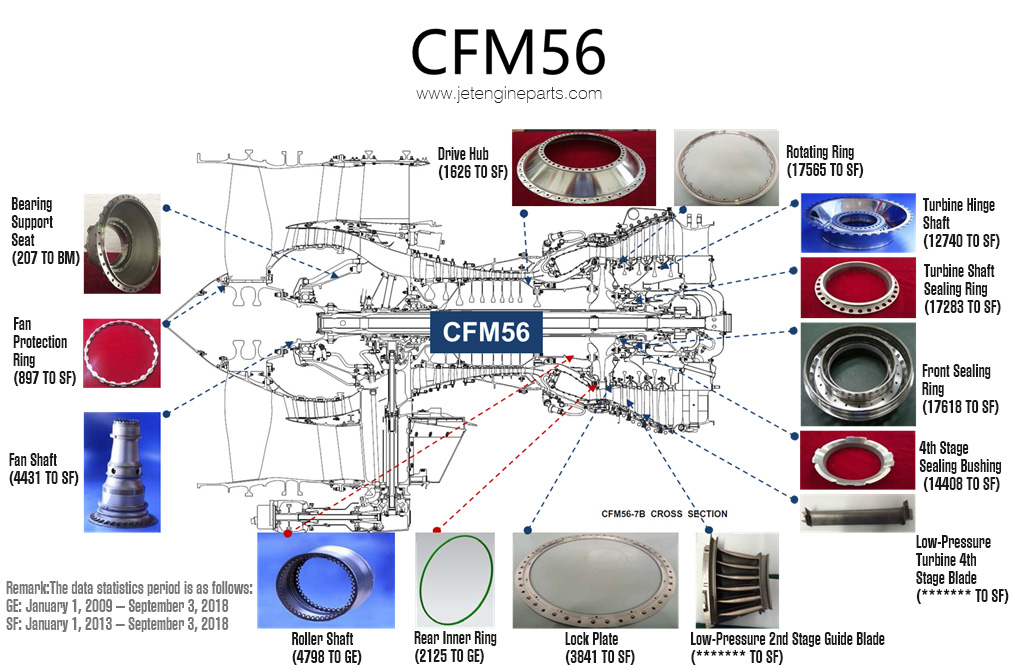

The Compressor Drum Shaft is a high-performance component designed for the CFM56 engine, which powers aircraft such as the Boeing 737 Classic series and Airbus A320 family. This critical part ensures mechanical stability and efficient energy transfer within the compressor and turbine systems, optimizing engine performance. Made from advanced nickel-based superalloys and titanium alloys, it withstands extreme temperatures, high pressures, and corrosion. Its precision engineering guarantees reliability, fuel efficiency, and extended engine lifespan, making it an indispensable component in modern aviation.

The Compressor Drum Shaft, a core component in the CFM56 engine series, plays a critical role in the operation of the aircraft’s compressor and turbine systems. Designed to endure the extreme temperatures and pressures of jet engine operations, this component ensures mechanical stability, seamless energy transfer, and prolonged engine reliability. Specifically engineered for use in Boeing 737 Classic series and Airbus A320 family aircraft, the Compressor Drum Shaft exemplifies advanced materials science and precision manufacturing.

This article explores the key technical features, material composition, and applications of the Compressor Drum Shaft, emphasizing its significance in aviation engine performance.

Material Composition: The shaft is constructed from nickel-based superalloys such as Inconel 718 and Waspaloy, capable of withstanding operational temperatures exceeding 700°C and pressures generated within the compressor and turbine assemblies.

Thermal Stability: The addition of thermal barrier coatings (TBCs), such as yttria-stabilized zirconia (YSZ), enhances the shaft’s ability to resist thermal fatigue and maintain its structural integrity during long-haul flights.

Engine components are frequently exposed to high-velocity gases, moisture, and environmental contaminants. The Compressor Drum Shaft incorporates oxidation-resistant nickel and cobalt alloys alongside anti-corrosion surface treatments, ensuring durability and reducing long-term wear.

Advanced Titanium Alloys: In certain compressor stages, the shaft utilizes lightweight materials such as Ti-6Al-4V, reducing the overall engine weight without compromising strength.

Structural Optimization: Features such as integrated cooling passages and stress-relief design minimize rotational stress and enhance fatigue life under high-speed conditions.

Exact Tolerances: The shaft is manufactured with tolerances in the micron range to ensure perfect alignment between the compressor and turbine stages.

Dynamic Balance: Its aerodynamic design mitigates vibration and maintains stability during high-speed rotations, improving overall engine efficiency.

Certifications: Each Compressor Drum Shaft meets FAA and EASA certification standards. Manufacturing processes are aligned with stringent aerospace quality management systems, including AS9100D and NADCAP.

The drum shaft connects the engine’s compressor and turbine stages, enabling seamless mechanical energy transfer. This ensures the rotation of the compressor blades, which compress incoming air for combustion, and the turbine blades, which extract energy from exhaust gases.

By maintaining precise alignment of the compressor and turbine assemblies, the shaft minimizes energy loss due to vibration or misalignment. This optimization improves the engine’s thrust-to-weight ratio and reduces specific fuel consumption (SFC).

The shaft evenly distributes mechanical stress across the connected assemblies, minimizing localized strain. This not only reduces wear on critical components but also extends the overall lifespan of the engine.

The robust design of the Compressor Drum Shaft ensures consistent performance under extreme conditions, reducing the risk of in-flight mechanical failures and enhancing passenger safety.

Nickel-based alloys such as Inconel 718 are chosen for their excellent high-temperature mechanical properties, including:

Tensile Strength: Maintains rigidity at elevated temperatures.

Fatigue Resistance: Withstands repetitive cycles of mechanical stress without cracking.

In low-temperature compressor stages, Ti-6Al-4V is employed for its lightweight properties and high strength-to-weight ratio, which contribute to fuel efficiency and reduced engine weight.

TBCs like YSZ enhance heat resistance by reflecting heat away from the shaft’s core, reducing thermal stress and extending the component’s operational lifespan.

The Compressor Drum Shaft is a standard component in the CFM56 engine series, which powers aircraft such as:

Boeing 737 Classic series (737-300, 737-400, 737-500)

Airbus A320 family (A318, A319, A320, A321)

This shaft’s compatibility across multiple aircraft types underscores its importance in supporting efficient and reliable operations for short- and medium-haul routes.

Liyan International utilizes state-of-the-art equipment and precision machining processes to produce Compressor Drum Shafts that meet the stringent tolerances and performance requirements of modern aviation engines.

Liyan International is a trusted supplier to leading airlines and Maintenance, Repair, and Overhaul (MRO) providers, recognized for delivering components that enhance fleet reliability and efficiency.

From material selection to delivery, our dedicated team works closely with clients to provide tailored solutions, ensuring seamless integration into existing engine systems.

Durable materials and precise construction reduce the frequency of repairs and replacements, translating into significant cost savings over the engine’s lifecycle.

The shaft’s optimized design minimizes energy losses, enhancing overall engine performance and reducing fuel consumption.

By maintaining consistent performance, the Compressor Drum Shaft supports high-utilization schedules, minimizing downtime for airlines.

The Compressor Drum Shaft for CFM56 engines is a testament to the advances in aerospace engineering and material science. Its critical role in ensuring energy transfer, efficiency, and safety makes it indispensable for modern aircraft operations.

For durable, high-performance aviation components, trust Liyan International. Our precision-engineered Compressor Drum Shafts are designed to meet the rigorous demands of the aviation industry, ensuring reliability, efficiency, and safety.

Looking for premium-quality Compressor Drum Shafts? Contact us today to learn more about our aerospace solutions and how we can support your aviation needs. Optimize your fleet with Liyan International.

Contact: Sales Dept.

Phone: 86-18068808880

Tel: 86-13905198660

Email: jetengineparts@aliyun.com

Add: No. 555, Yangzijiang Road, New District, Zhenjiang City, Jiangsu Province, China

We chat